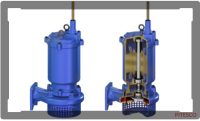

Description

Hyosung’s vertical roller mill gear unit technology is based on the know-how and technical capacity accumulated for the past 20 years and the technical agreement with RENK and has been supplied to both domestic and international customers. Playing a core role in grinding fuel for thermal power plants and cement plants, the vertical roller mill gear unit has excellent durability against severe environments and is able to handle high loads. A temperature sensor is mounted on the vertical roller mill gear unit to monitor temperatures of the bearing and the oil. In addition, a combination of the planetary gear and the bevel gear enables Hyosung to design the reducer with a gear ratio of 20:1~40:1.

Features

- Drives the bevel gear and the planetary gear in a straight line in two stages

- Welded case without any cracks

- Uses a shaft thrust bearing lubricated hydrostatically or hydrodynamically

- Applies lubrication and cooling to the gearing and gear bearing according to the isolated oil supply system’s oil pressure.

Scope of Production

Output

365kW (KPAV90) / 515kW (KPAV100) / 700kW (KPAV125) / 915kW (KPAV140) / 1050kW (KPAV160) / 1350kW (KPAV180)

Gear ratio

26.31:1 (KPAV90) / 25.6:1 (KPAV100) / 28.6:1 (KPAV125) / 30.0:1 (KPAV140) /

34:1 (KPAV160 & KPAV180)

Rotating Speed

1000rpm (KPAV90) / 900rpm (KPAV100) / 1000rpm (KPAV125) / 900rpm (KPAV140) /

1000rpm (KPAV160 & KPAV180)

Weight

8,000kg (KPAV90) / 10,000kg (KPAV100) / 17,000kg (KPAV125) / 23,000kg (KPAV140) /

32,000kg (KPAV160) / 40,000kg (KPAV180)

Size (LxWxHm)

1.5x1.5x1.2m (KPAV90) / 1.6x2.0x1.5m (KPAV100) / 2.0x2.3x1.6m (KPAV125) /

2.5x2.3x1.6m (KPAV140) / 2.9x2.5x1.7m (KPAV160) / 3.0x2.8x2.1m (KPAV180)