As a pioneer of wind farm engineering in Korea, Hyosung have contributed to renewable energy and environmental preservation. We embarked on our wind turbine system business in the mid-1990s and have since established the best technologies through development of wind turbine system’s components, such as gearboxes, generators, controllers and towers. In 2005, we developed Korea’s first geared-type 750kW wind turbine and successfully commercialized it with outstanding reliability and stability. Moreover, we developed a 2MW wind turbine system which is now under test operations.

We will continue to develop the wind turbine system industry with an offshore 5MW wind turbine system and by expanding our product line-up continuously in the future. We intend to become one of the top ten wind turbine system manufacturers by 2018 based on our technical capabilities of wind turbine system components and comprehensive engineering capabilities.

With respect for people and the environment, Hyosung strives to become a global green energy company by delivering wind energy to the world.

Hyosung’s HS90 2MW wind turbine is a three bladed, pitch regulated upwind wind turbine with active yaw system. The rotor has three-bladed pitch bearings with full span control. The rotor has a variable pitch system. It helps the blade to be operated in optimized angles at all times to maximize the power production.

Rotor

The rotor of HS90 consists of a hub made of cast iron, three blades and the pitch regulation system. The blade bearings connect hub and each blade.

Blades

The blades are 43.8 meter long and are equipped with a lightning receptor at the tip. The steel cable inside the lightning receptor protects the blade and the hub from lightning. The distance between the root of the blade and the center of the hub is 1.5 meter and, as a result, the diameter of the rotor is 90.6 meters

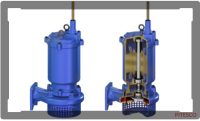

Gearbox

The main gear transmits torque and revolutions from the rotor to the generator. The gear unit is a combination of 2-stage planetary gear and 1-stage helical gear. The main shaft that is connected from the rotor is mounted into an input shaft of the gearbox with shrink disc. Two torque arms support the gearbox, and the hydraulic dampers that is positioned between the torque arm and main frame absorbs the torque and the oscillations. Finally torque is transmitted from the high speed shaft to the generator via a flexible composite coupling that is located between the high speed shaft and generator and behind the brake disc. The brake disc is mounted directly on the high-speed shaft. The gearbox lubrication system is a forced feed system with integrated oil pump.

Generator

The generator has been designed as three-phase asynchronous generator with slip rings. The design maximizes reliable operation and high availability by using the high voltage F-class insulation technology. This ensures a long life span and provides a high momentary overload capacity. The generator is built in accordance with the principal international safety standards.

Yaw system

Yaw system is used to rotate the nacelle that is positioned on the top of tower with its bearing, in order to keep the turbine facing the wind and to untwist the power and other cables when they become excessively twisted. It consists of 4 electric motors installed inside the nacelle, which drives a pinion mounted on a vertical shaft via gear reducer.

Tower

HS90 is mounted on a tapered tubular steel tower which is made of four sections