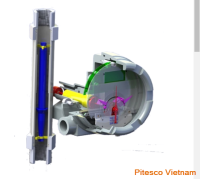

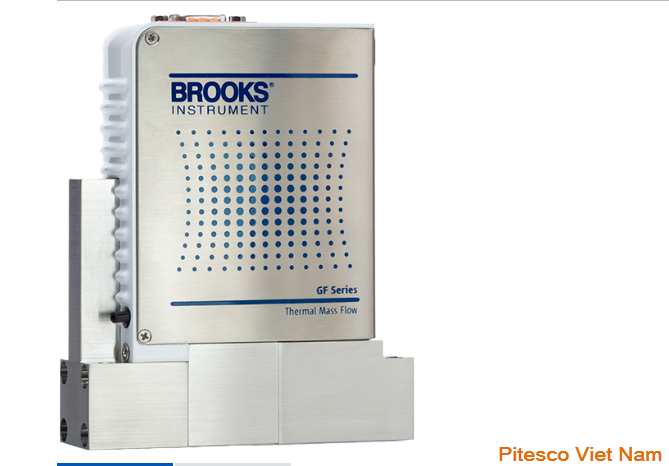

GF135 Series Real-Time Flow Error Detection Metal Sealed Thermal Mass Flow Controllers

Xuất sứ: USA

Nhà cung cấp: Pitesco

Hãng sản xuất: Brooks Instrument

Models GF135

Keep critical flow processes on-target and maximize throughput with the GF135 Advanced Diagnostics Pressure Transient Insensitive (PTI) mass flow controller. The world’s first “smart” mass flow controller is a true game changer: It performs integral rate-of-decay flow measurement without stopping the flow of process gas. It allows semiconductor manufacturers to verify process gas accuracy, check valve leak-by and monitor sensor stability in real time without removing the flow controller from the gas line.

Combined with an all-metal wetted flow path, ultra-fast settling times and industry-leading process gas accuracy, the GF135 PTI MFC has the potential to transform the productivity and throughput rates for a wide range of deposition processes.

GF135

Flow Range (Full Scale Capacity) 3 sccm - 5 slm (N2 Eq.)

Response Time <300 ms (<860 sccm N2 equivalent)

<400 ms (861-5000 sccm N2 equivalent)

(to within ±2% FS)

Gases Supported Ar, BCl3, C4F6-q (@ 800 Torr), C4F8 (@ 1200 Torr), C5F8, CF4, CH2F2, CH3F, CHF3, Cl2, CO2,

H2, HBr, He, N2, N2O, NF3, NH3, O2, SF6, SiCl4 (@ 100 Torr), SiH2Cl2, SiH4, SiHCl3

Rate-of-Decay Performance ROD by default is disabled/off. It should not be enabled until after the MFC is installed and properly commissioned.

Surface Finish 4µ inch Ra