K05-TS-MOR-3.00 TS BLOWERS 2 impellers - Single Stage

Hãng sản xuất: FPZ

You can buy the FPZ K05-TS-MOR-3.00 blower in one of the following ways:

Dich vụ sửa chữa, bảo dưỡng, cải tiến các hệ thống dây chuyền tự động công nghiệp

1. Call the sales department: 8 (495) 669-34-43 .2. Send a request to info@fpz.moscow .

3. Through the form on our website: go to fill the form .

| Model: | K05-TS-MOR-3.00 |

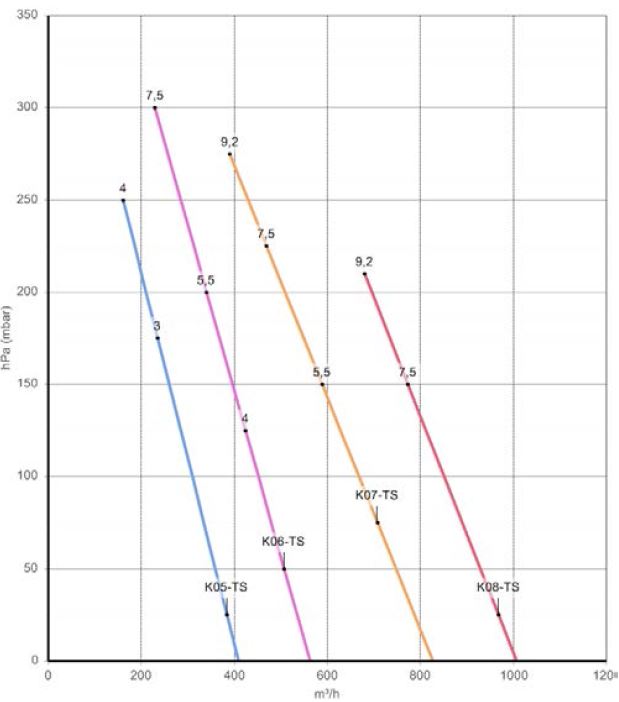

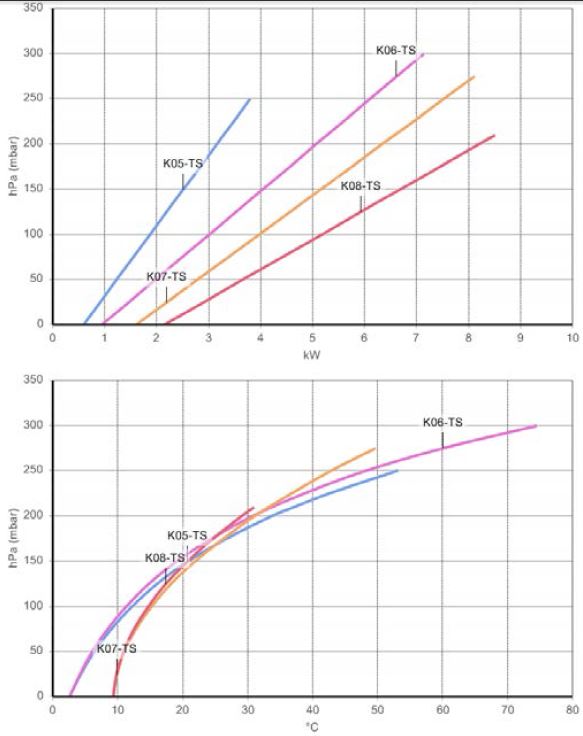

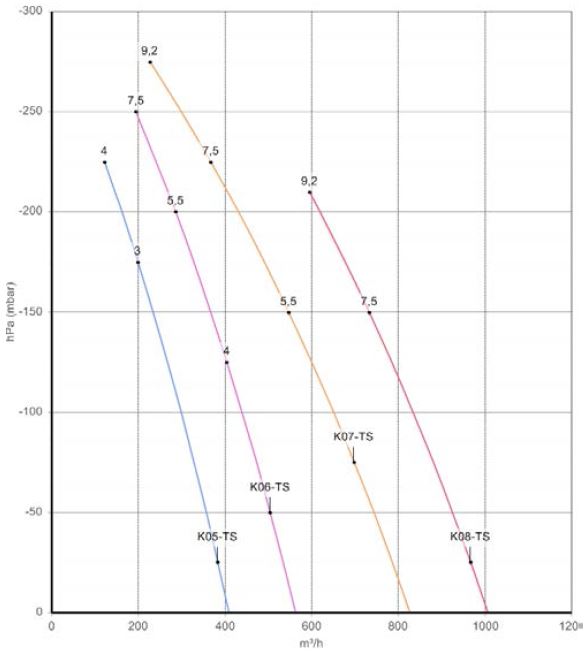

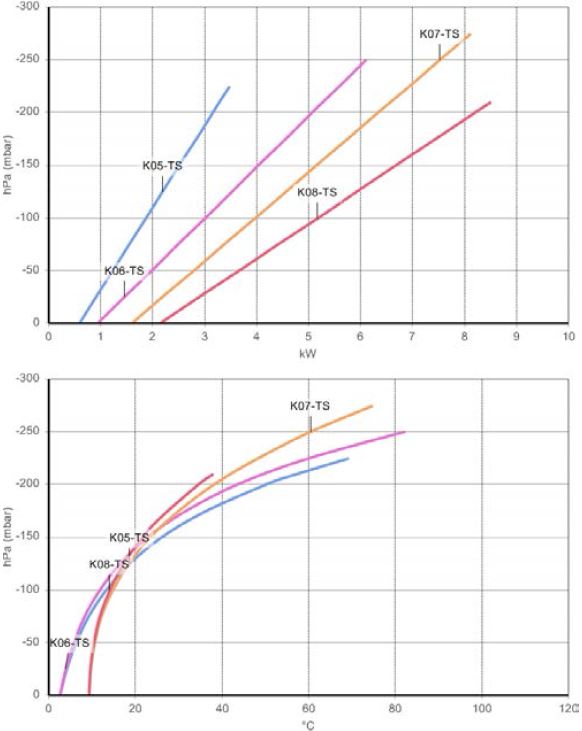

| Performance | 409 m3 / hour |

| Power | 3.0 kW |

| Residual pressure | 175 mbar |

| Mains frequency | 50 Hz |

| Engine speed | 2900 rpm |

| Noise | 71.5 dB (A) |

| Weight | 50.0 kg |

| Performance | 409 m3 / hour |

| Power | 3.0 kW |

| Residual pressure | 175 mbar |

| Mains frequency | 50 Hz |

| Engine speed | 2900 rpm |

| Noise | 71.1 dB (A) |

| Weight | 50.0 kg |

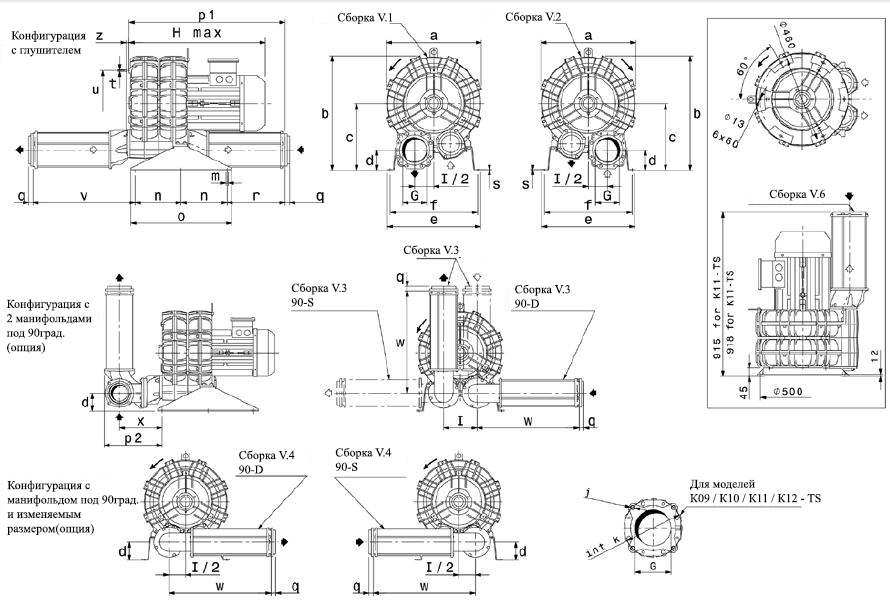

DIMENSIONS, mm

| a | b | c | d | e | f | G | H | i | j | k | m | n | o | p1 | p2 | q | r | s |

| 327 | 422 | 258 | 77 | 404 | 374 | G 3 " | 495 | 150 | - | - | 13 | 300 | 345 | 634 | 249 | 25 | 328 | four |

DIMENSIONS mm

| t | u | v | w | x | z |

| M8 | 200 | 436 | 481 | 176 | nineteen |

FPZ Swirl Blowers

FPZ Eddy Blower Industries

Vortex blowers FPZ are used in many industries, such as: ceramics , chemistry, pharmaceuticals , cleaning , electronics , food , glass , printing , medicine , metal , packaging , plastics , textiles , woodworking .Execution and supply of FPZ blowers

FPZ blowers are delivered in various executions:- Standard Direct Drive Blower FPZ Blowers

- Energy Saving Direct Drive Eddy Blowers

- Energy saving FPZ blowers of horizontal layout Flex-Coupling with clutch

- Energy-saving FPZ blowers with vertical Flex-Coupling layout with clutch

- Explosion proof vortex blowers FPZ ATEX with explosion protection category 2G

- Explosion Proof FPZ ATEX Blowers with 3GD Explosion Protection Category

- Vortex blowers of special design are made on request.

Features of FPZ blowers

FPZ has developed an IE2 blower engine capable of delivering the required performance with reduced power consumption compared to a standard engine. FPZ blowers are available interspersed with additional seals, anodized coating, stainless screws and special protection against aggressive gases. In many areas where vortex blowers are installed, explosion protection is required. Some types of dust and gas have high explosion risks. Even a small spark can lead to unpredictable consequences. Explosion-proof blowers FPZ ATEX certified, guarantee the appropriate level of explosion protection systems for systems operating in explosive areas (category 2G) and areas where the probability of an explosion is small (category 3GD). Two-pole electric motors, three-phase asynchronous motors, tropical version F, protection class - IP55 are installed.Range of operation of FPZ blowers

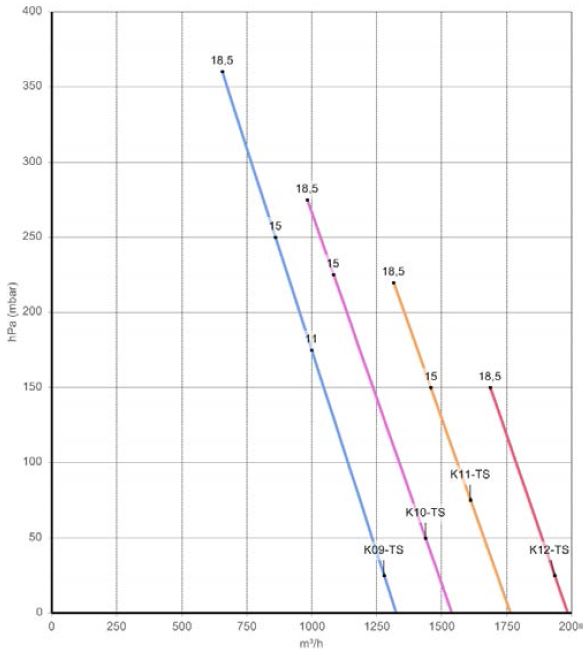

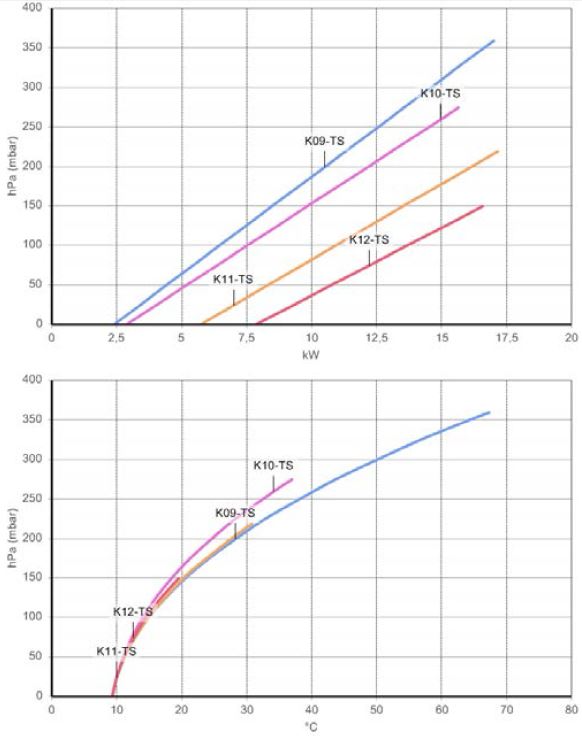

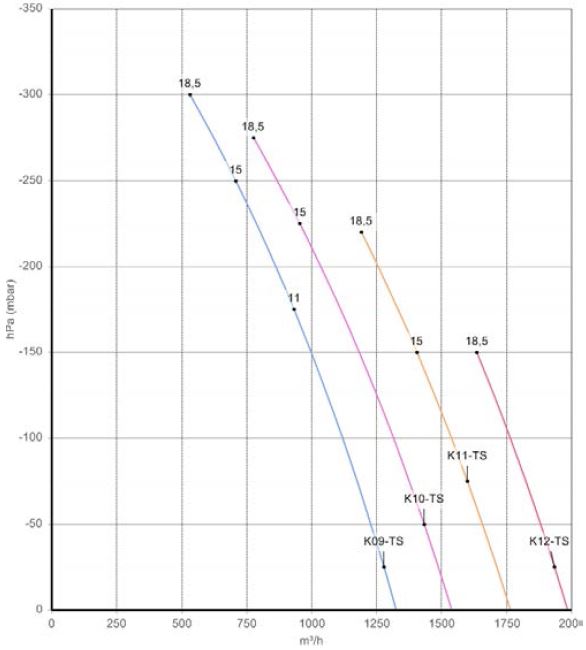

FPZ industrial blowers operate in the following ranges:- Capacity from 137 m3 / h to 1985 m3 / h for versions with two impellers

- Residual pressure from 82 mbar to 750 mbar

- Electric motor power from 0.20 kW to 37 kW

FPZ blower production

FPZ alsosupplies a full range of accessories , including filter, safety valves, diverting valves, flexible hoses, tees, silencers and sensors.

FPZ alsosupplies a full range of accessories , including filter, safety valves, diverting valves, flexible hoses, tees, silencers and sensors. They require not only our products, but also the quality and experience gained through solving many complex problems. Each production phase is controlled by CNC. Blower is made in 2 stages. The first stage includes the production of the engine and the body, after which the device is configured in the second stage, which requires preparation. The manufacture of the impeller includes making the desired shape and deburring to remove all traces of foundry sand. Then comes the balancing. The other part is called the lid, produced on a CNC machine. We constantly We constantly strive to improve the efficiency of our products, Aware of the need to use environmentally friendly materials. One of the features of our blowers is their efficiency. We managed to achieve a high level of performance due to the optimization of the hydrodynamics of our components.

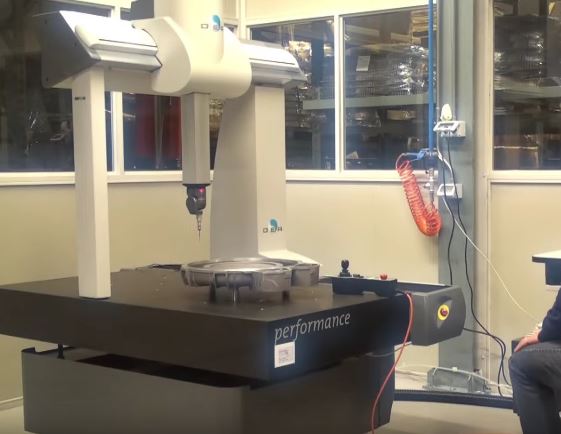

They require not only our products, but also the quality and experience gained through solving many complex problems. Each production phase is controlled by CNC. Blower is made in 2 stages. The first stage includes the production of the engine and the body, after which the device is configured in the second stage, which requires preparation. The manufacture of the impeller includes making the desired shape and deburring to remove all traces of foundry sand. Then comes the balancing. The other part is called the lid, produced on a CNC machine. We constantly We constantly strive to improve the efficiency of our products, Aware of the need to use environmentally friendly materials. One of the features of our blowers is their efficiency. We managed to achieve a high level of performance due to the optimization of the hydrodynamics of our components.  New technologies are the driving force behind FPZ, allowing you to customize products to satisfy customers quickly and efficiently. In fact, our advanced technologies allow us to produce products both with and without CNC. Every FPZ blower produced at the factory is checked. Consequently, we can guarantee high quality. In the metrology shop we have a coordinate measurement machine that allows you to control all the dimensions of the components. We conduct functional testing under normal and extreme use conditions. An air blower FPZ with a side channel is actually a very simple product. It consists of body and cover. In the housing there is a rotor, also called an impeller. The rotor is mounted on the motor shaft. We never stop searching for new ideas and innovations; we strive to put them into practice with enthusiasm.

New technologies are the driving force behind FPZ, allowing you to customize products to satisfy customers quickly and efficiently. In fact, our advanced technologies allow us to produce products both with and without CNC. Every FPZ blower produced at the factory is checked. Consequently, we can guarantee high quality. In the metrology shop we have a coordinate measurement machine that allows you to control all the dimensions of the components. We conduct functional testing under normal and extreme use conditions. An air blower FPZ with a side channel is actually a very simple product. It consists of body and cover. In the housing there is a rotor, also called an impeller. The rotor is mounted on the motor shaft. We never stop searching for new ideas and innovations; we strive to put them into practice with enthusiasm.

FPZ blowers are used in various industries. Main applications:

- FPZ blowers for degassing

- FPZ blowers for moving operations

- FPZ blowers for pneumatic conveying

- Fluidized FPZ Blowers

- Reduction of drying time due to the creation of vacuum by FPZ blowers

- FPZ blowers are used for surface treatment, coating

- Evacuation of evaporation (obtaining evaporation at lower temperatures)

- FPZ blowers are used in the packaging process.

- Room cleaning

- FPZ vacuum cleaning machines, removing liquids and solids from the floor

- Oily steam removal

- Capture and utilization of biogas

- FPZ blowers in tare filling processes

- FPZ blowers for humidification in the food industry

- Centralized vacuum systems

- Uniform cooling due to FPZ equipment

- Compressing gas by FPZ blowers for further pumping

- FPZ equipment is used in the sealing process.

- Filtration systems

- Pneumatic presses

- Steam deodorization

- Surface treatment with granules (sand)

- Air cushion motion using FPZ blowers

- Vacuum table

- Air mattresses. Air supply vacuum systems FPZ

- Filling machines in production

- Vacuum systems for heat sealing, thermoforming

- Water purification systems, fisheries

- Pool Equipment: Purification, Artificial Waves