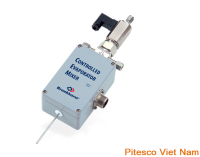

Ex-Proof Coriolis Mass Flow Meter/Controller for low flow rates

Xuất sứ: Holland

Nhà cung cấp: PITESCO VIET NAM

Hãng sản xuất: Bronkhorst

MINI CORI-FLOW EX D XM14

Ex-Proof Coriolis Mass Flow Meter/Controller for low flow rates

- High accuracy, excellent repeatability

- Fast response

- Independent of fluid properties

- Additional density and temperature output

- IECEx and ATEX Zone 1 approved

Ex-proof Coriolis Mass Flow Meters/Controllers for low flow rates

mini CORI-FLOW Ex d Mass Flow Meters are precise and compact instruments for low flow rates, based on the Coriolis measuring principle, built in an explosion proof housing for use in IECEx and ATEX Zone 1 hazardous areas, ATEX approval II 2 G Ex d e IIB T6 Gb. Bronkhorst® model XM14 Mass Flow Meter (MFM) is suited for highly accurate measurement of gas or liquid flow ranges between 0,03…1 kg/h and 0,3…30 kg/h (which corresponds with 0,4…13,3 ln/min up to 4…400 ln/min when used on nitrogen) at operating pressures up to 107 bar (a).

The instrument contains a microprocessor based pc-board with signal and fieldbus conversion and a PID controller for optional mass flow control by means of a separately mounted control valve or pump.

Technical specifications

|

Measurement / control system |

|

|---|---|

|

Mass flow accuracy |

Liquid: ±0,2% of rate; |

|

Turndown |

Meter: up to 1:100; |

|

Repeatability |

±0,05% of rate ± ½(ZS* x 100/flow)% based on digital output |

|

Zero Stability (ZS)* |

< ±6 g/h |

|

Response time, meter (t98%) |

≤ 200 msec |

|

Settling time, controller |

1 sec. (typical) |

|

Temperature range |

Ambient temperature range: 0...55°C |

|

Temperature effect** |

on zero: < 0,5 g/h/°C; |

|

Temperature accuracy |

±0,5°C |

|

Density accuracy |

< ±5 kg/m3 |

|

Mounting*** |

Any position, attitude sensitivity negligible |

|

Leak integrity |

Outboard < 2 x 10-9 mbar l/s He |

|

Warm-up time |

> 30 min. for optimum accuracy |

|

Mechanical parts |

|

|---|---|

|

Material (wetted parts) |

stainless steel 316L or comparable |

|

Sensor |

single tube, DN 1.3 |

|

Pressure rating |

107 bar abs |

|

Process connections (welded) |

1/8" OD compression type; other on request |

|

Seals |

metal |

|

Valve seat (controllers) |

Kalrez®-6375, other on request |

|

Ingress protection (housing) |

IP66 |

|

Electrical properties |

|||

|---|---|---|---|

|

Power supply |

+15…24 Vdc +/- 10% |

||

|

Max. power consumption |

Meter: max. 3 W; |

||

|

Analog output |

0...5 (10) Vdc, min. load impedance > 2 kΩ; |

||

|

Analog setpoint |

0...5 (10) Vdc, min. load impedance > 100 kΩ; |

||

|

Digital communication |

standard: RS232; |

||

|

Electrical connection |

All instrument connections are wired to screw terminals |

||

|

External actuator options to be connected to the controller |

|

|---|---|

|

Electromagnetic control valve (Bronkhorst®) |

C2I valve with XC coil or XB coil through barrier |

|

Pneumatic actuated control valve (Badger Meter) |

RC200 valve with Ex d TEIP11 I/P converter |

|

Mass Flow Meter controlled pump |

Pump with ATEX zone 1 U/f converter |